MST-10

The Alphanetics MST-10 is a rugged Tank Floor Scanner used primarily for NDT and API 653 inspections. It uses a Patented combination of several different kinds of sensors to find metal loss in an Above Ground Storage Tank Floor using Magnetic Flux Leakage.

Technology

The precision Sensor Bar is manufactured using techniques and materials that makes each Sensor Bar interchangeable and very rugged.

The MST-10 is designed to have even sensitivity across the entire scan area. There are no low sensitivity areas or gaps that can cause metal loss to be missed.

The electronic hardware is designed to have very low noise. This allows the embedded software to implement a noise reduction algorithm to eliminate almost all false indications.

Patented technology, that uses several different types of sensors, makes the MFL readings more accurate and reliable.

The Wheel Height adjustment uses a Patented technique that is rugged but simple to set and use.

The MST-10 was designed with special electronic components so it can be operated at temperatures well below freezing (range is -20C to 70C).

TECHNOLOGY

Custom designed low noise cables are potted with an oil resistant epoxy at each connector. The Cables also have custom designed strain reliefs and use Military type connectors to make them rugged and reliable.

Corrosion resistant Stainless Steel and Titanium fasteners and hardware are used extensively in the MST-10.

The Electronics Box is sealed to IP65 so it can be operated in high humidity environments frequently found inside tanks.

Features

Both poles of the Magnetic Flux Assembly and the Sensor Bar are visible from the side of the scanner. This makes it easy to adjust the Magnetic and Sensor Bar heights.

The Handle breaks into two sections to make it easier to ship and operate in tanks on low legs.

The front panel switches and displays are lighted to make it easy to operate in low light conditions.

Custom designed ATA shipping containers are included to allow the MST-10 to be easily transported by truck or aircraft.

The MST-10 can be removed from the shipping containers, moved into a tank, and assembled into a working unit in just a few minutes.

A skilled operator can inspect a tank in a fraction of the time needed by other Tank Floor Scanners.

Features

No battery charger is needed because the MST-10 uses two standard sized Lantern batteries. The standard Lantern batteries can power the MST-10 for more than 3 weeks.

Since the MST-10 uses Alkaline batteries rather than a Lead Acid battery, it can be shipped via air carriers like FedEx and UPS.

The Magnetic Flux Assembly sends a strong magnetic field into the steel floor plates. The advantages are: 1) the unit can sit higher off the floor (which allows the scanner to run over humps and sags), 2) works with coated plates, 3) works with thicker tank floor plates, ans 4) can inspect lap welds.

The low profile design allows the MST-10 to pass under tank internals to inspect more of the tank.

The cables are routed to reduce damage during a tank inspection.

The front/back wheel design allows inspecting right next to the floor lap welds.

The adjustable handle bar and Electronics Box also allows inspection of the critical zone.

Since 1993

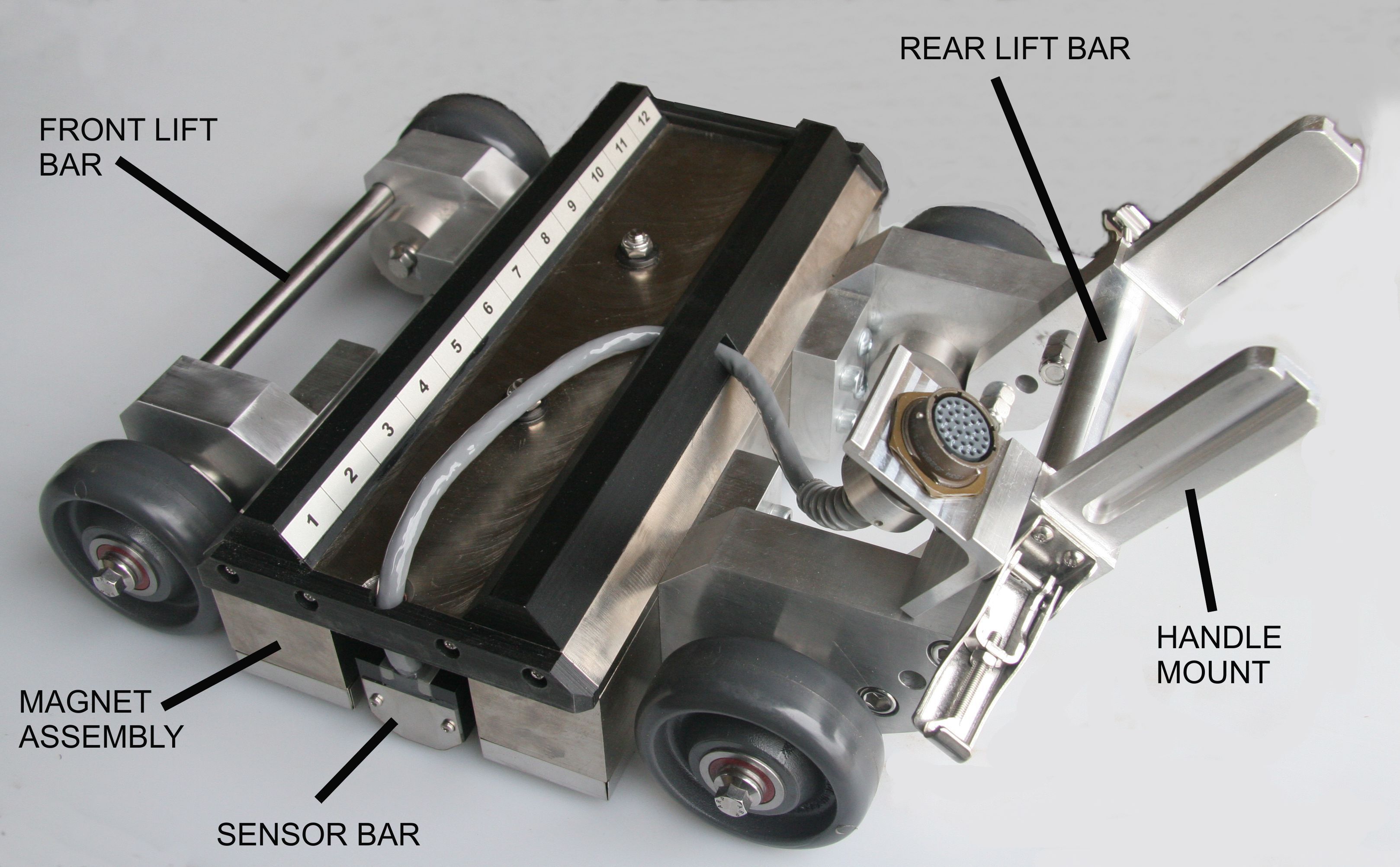

MAGNETIC FLUX ASSEMBLY

This assembly contains 1) front and rear lift bars, 2) wheels with Patent Pending height adjustment for Magnet height, 3) Multi Sensor Bar, 4) Magnetic circuit, 5) UHMW PE bumpers to protect scanner, 6) 1 to 12 channel label, 7) Sensor Bar connector mount, 8) Sensor Bar height adjustment nuts, and 9) mounts for the Handle.

Since 1993

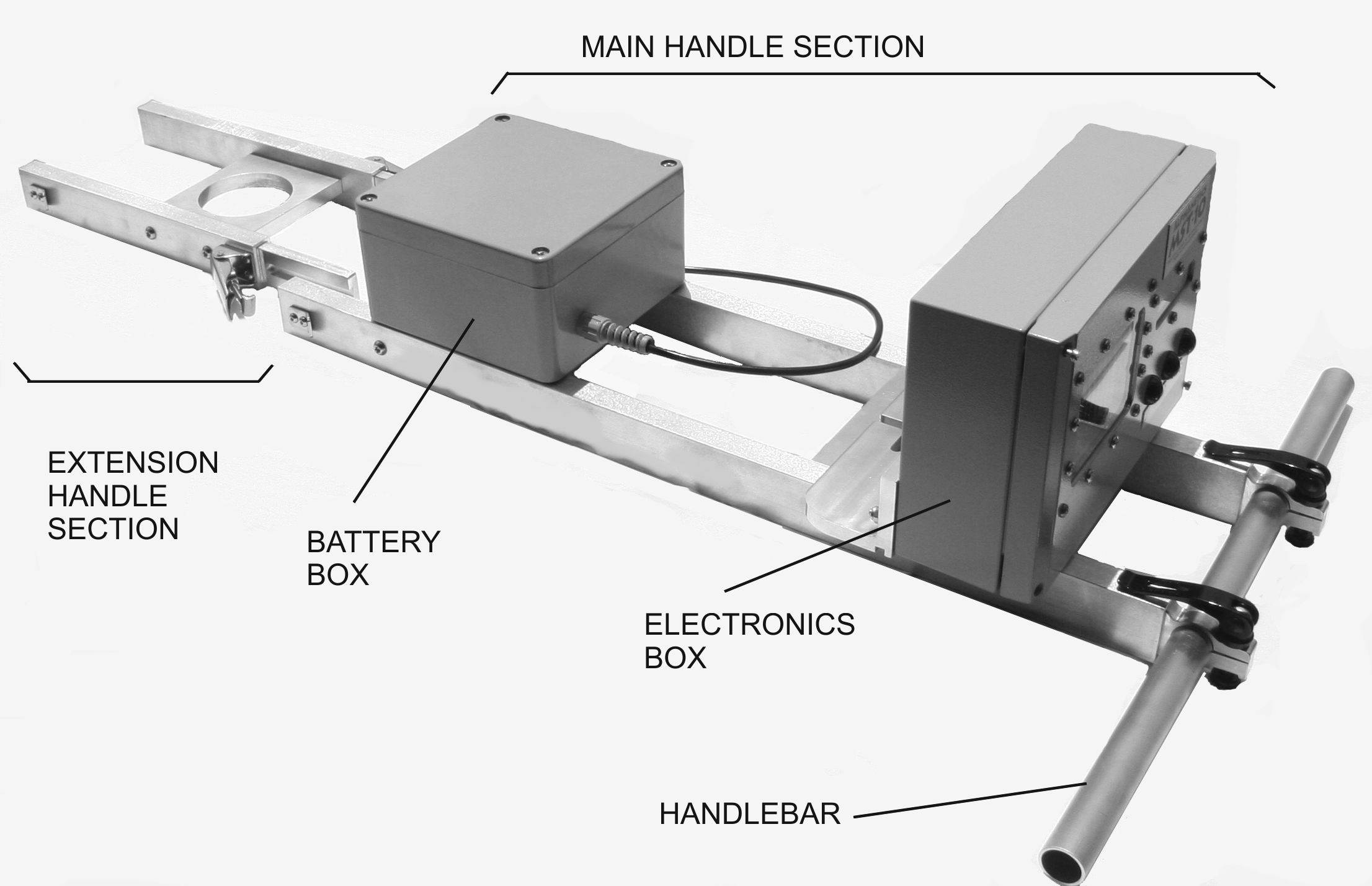

HANDLE SECTION

The MST-10 has four pieces: 1) Extension section, 2) Main section, 3) Electronics Box, and 4) Handle bar..

The Extension section can be removed to reduce MST-10 height if the tank is on low legs.

The Electronics box can be removed with a quick release lever for shipping or shifted to either side to allow inspection next to a wall.

The Handle bar can be removed or shifted using two quick release levers for shipping or to allow inspection next to a wall.

Since 1993

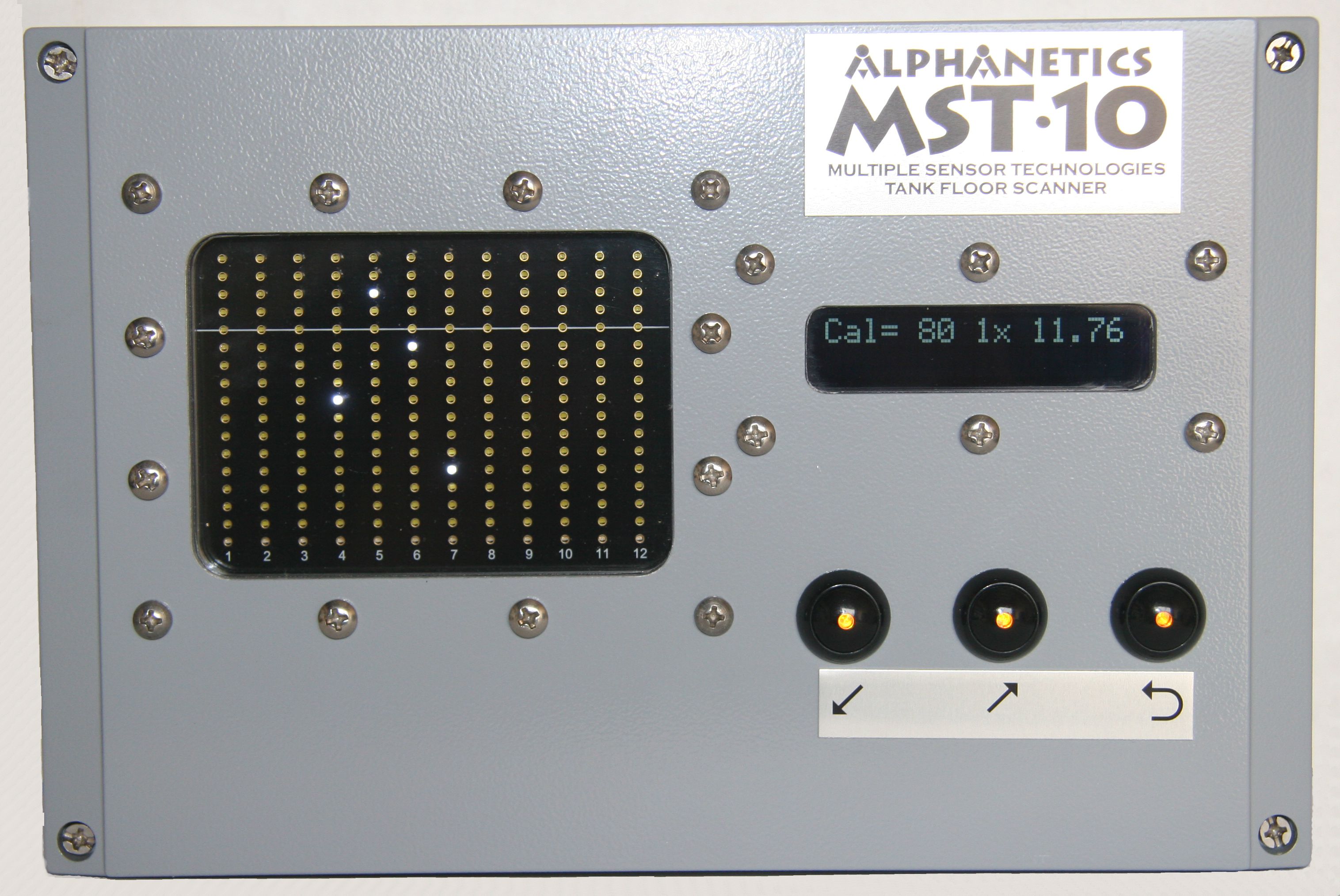

FRONT PANEL

The MST-10 Front Panel has three main sections: 1) the 12 channel LED signal display, 2) the LCD information display, and 3) the three lighted command switches.

The intensity of the LED display can be adjusted to work in dim or very bright conditions.

Since 1993

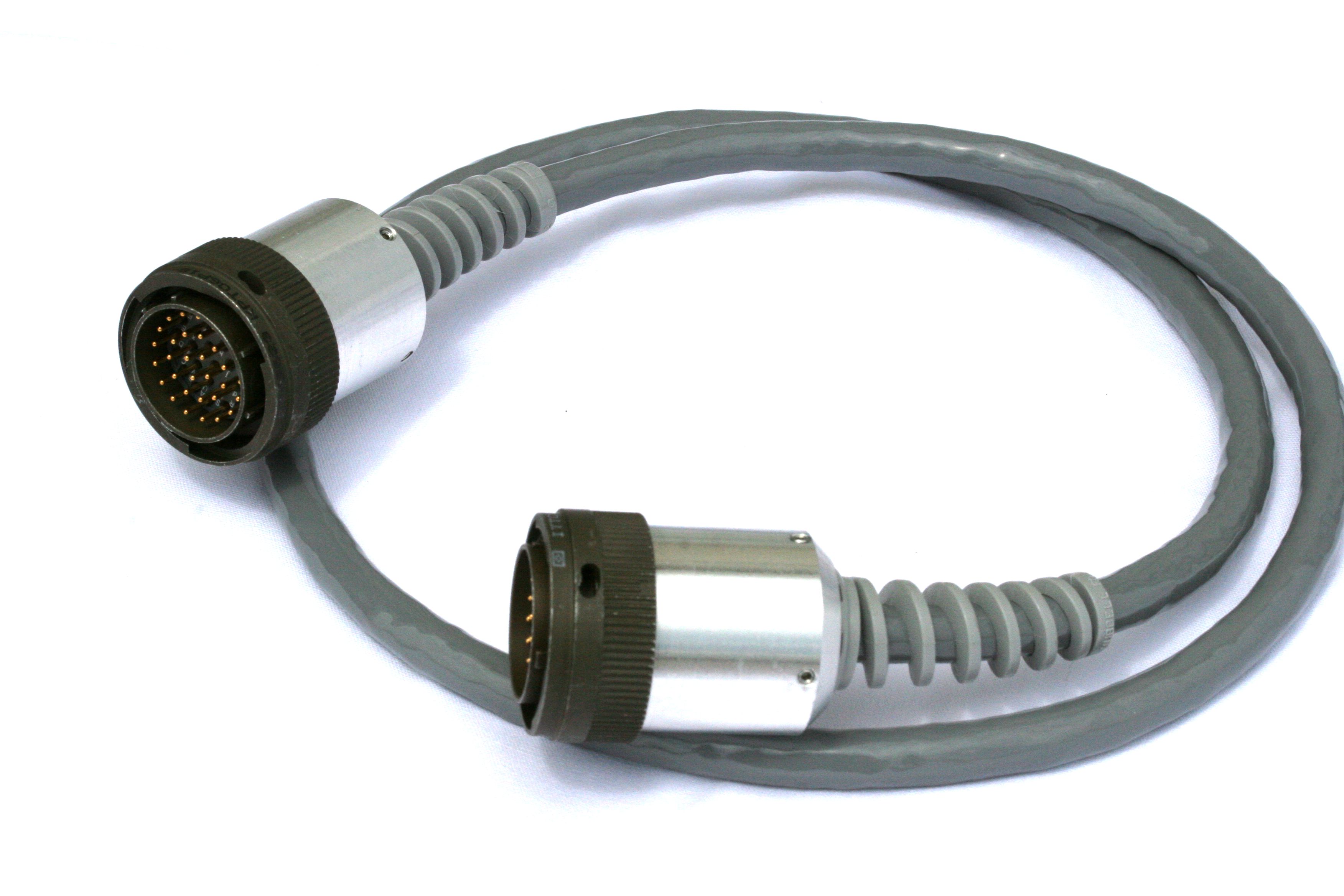

ELECTRONICS TO SENSOR BAR CABLE

This is an extremely rugged cable assembly that uses custom designed cable and custom designed potting shell/strain relief. The connectors are Military type sealed gold plated connectors for reliable connections.

Since 1993

CUSTOM ATA CASES

The MST-10 is typically transported in two custom designed ATA cases. This picture shows the case for the Magnetic Flux Assembly.